Unity Style FAST Optic Riser Mount: full guide and review

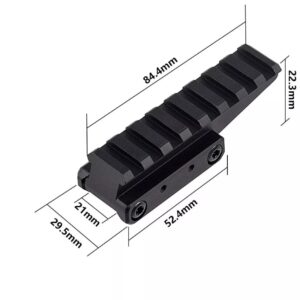

Reading Time: 2 minutesAt a glance Product: Unity Style FAST Optic Riser Mount Link: Unity Style FAST Optic Riser Mount Price: £20.00 Material: CNC aluminium, anodised Colours: Black, FDE Rail standard: M1913 Picatinny Mount type: Rail‑grabber clamp Top interface: Elevated M1913 Picatinny platform Compatibility: EXPS, UH‑1, and other lower 1/3 co‑witness optics; “Perfect